Introduction

Environmental protection is the most important common issue in the world in the 21st century. Global warming and the greenhouse effect have caused serious climate change problems due to rising temperatures. In recent years, the frequency of extreme climates has clearly increased, and it has caused huge economic losses and considerable casualties.

British scientists predict that if the greenhouse effect is not effectively reduced, the average temperature of the earth will rise by 4°C and the sea level will rise and submerge 1/6 of the earth's land as soon as 2060.

On April 22, 2016, the "Paris Climate Agreement" signed by representatives of 175 countries around the world replaced the "Kyoto Protocol", in which once again emphasized energy conservation and carbon reduction are the common responsibility of everyone in the world. Nowadays, all sorts of weather related emergencies, such as tornados, floods, mudslides, earthquakes or severe weather, are causing property damage or serious risk of injury over the world. Before the energy transition and green energy development reaching significant progress, it’ll benefit to everyone to actively implement energy conservation and carbon reduction.

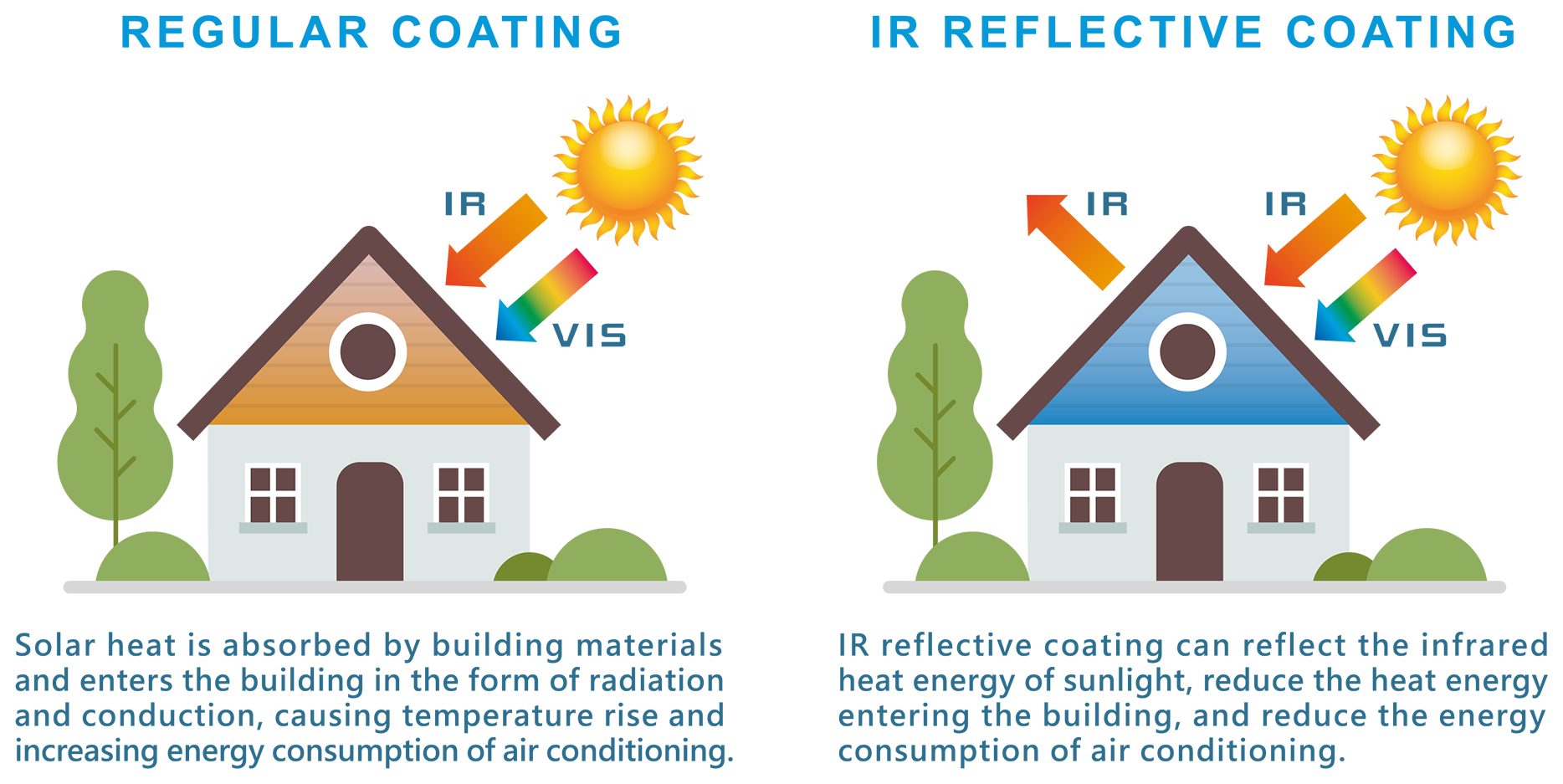

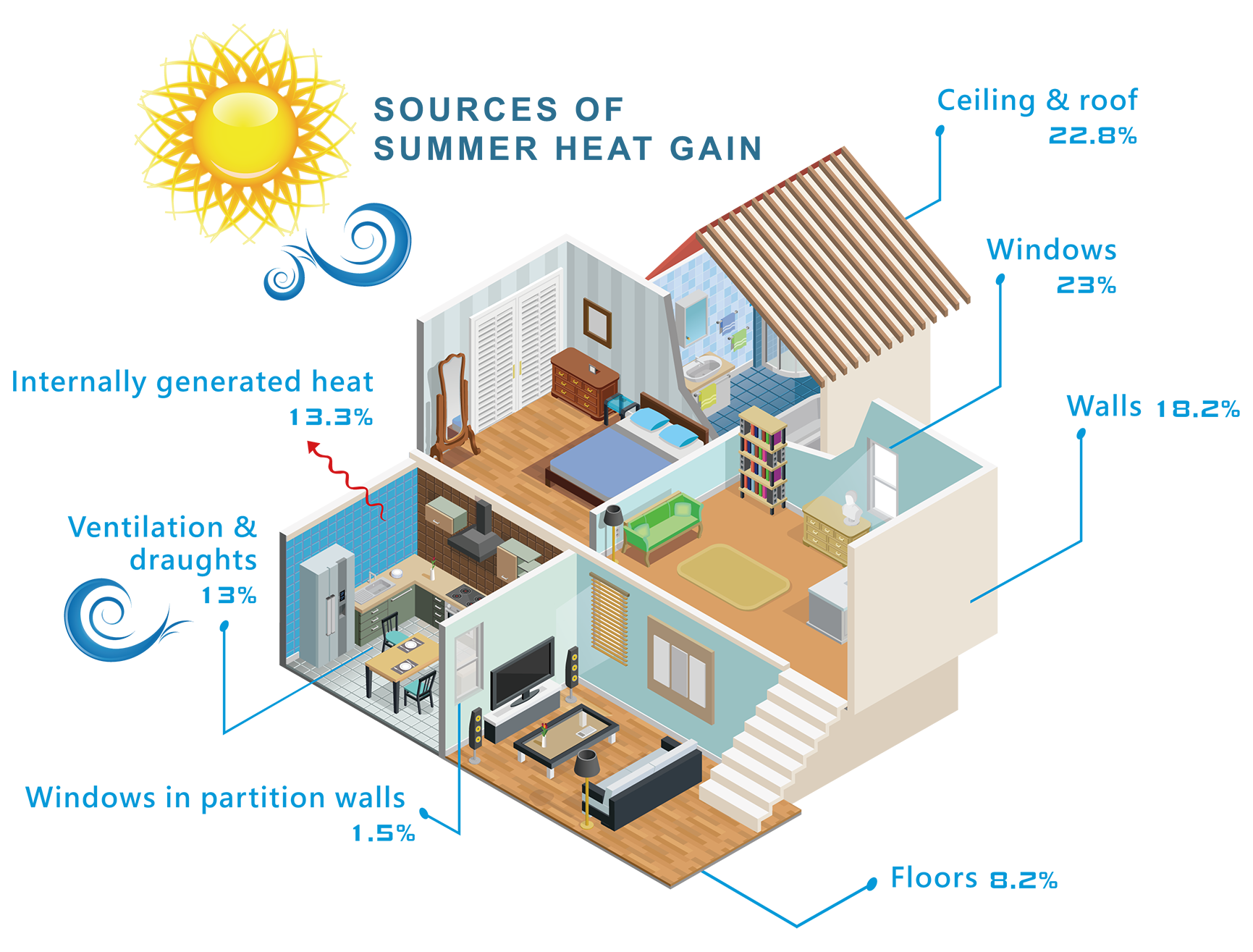

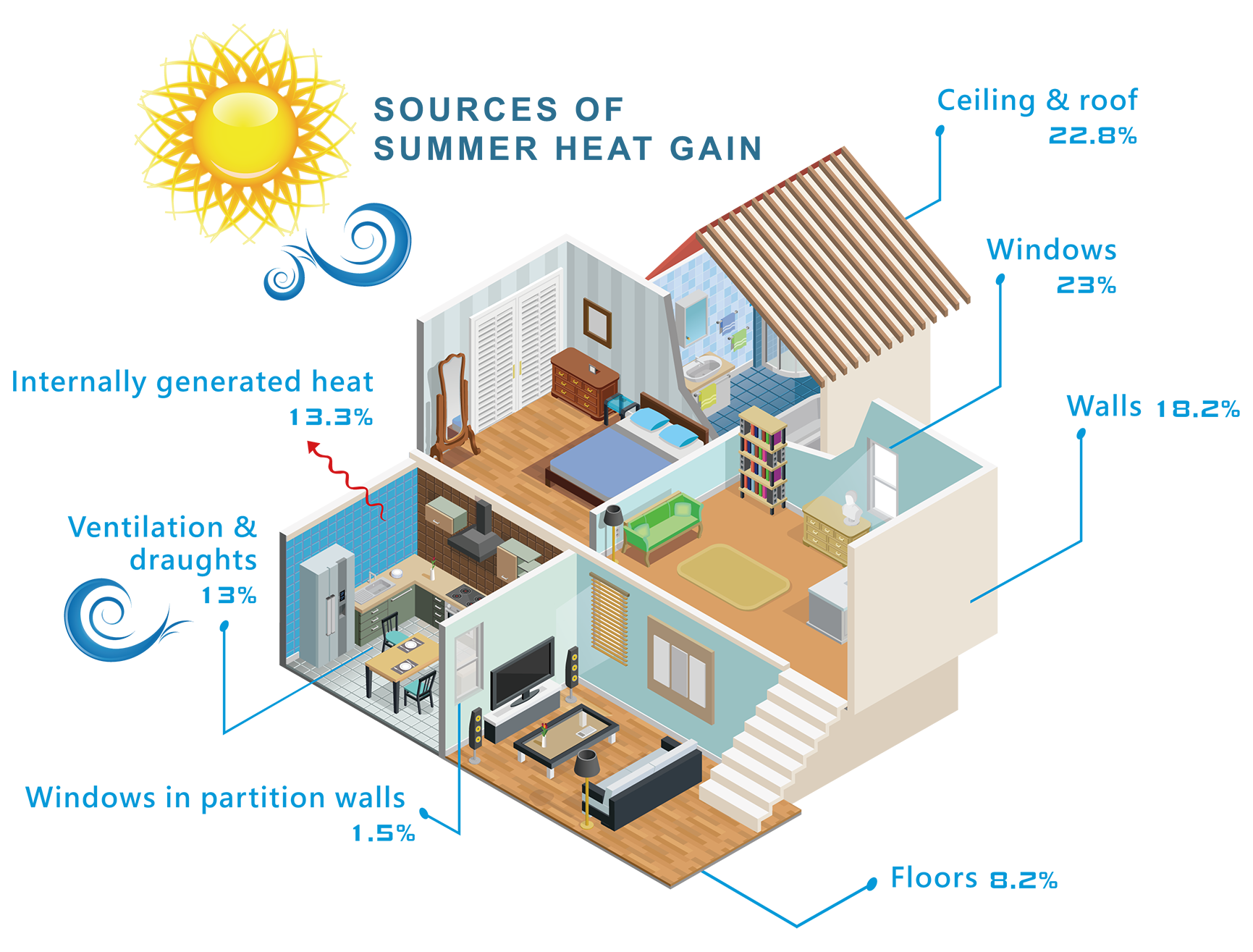

The major way to reduce energy consumption of buildings is either improving the energy efficiency of building equipment or reducing the energy consumption of building evelopes. The former includes the use of energy-efficient air conditioners and lighting, and the later includes the use of high-performance insulating panels, roofs and windows, etc.

The major way to reduce energy consumption of buildings is either improving the energy efficiency of building equipment or reducing the energy consumption of building evelopes. The former includes the use of energy-efficient air conditioners and lighting, and the later includes the use of high-performance insulating panels, roofs and windows, etc.

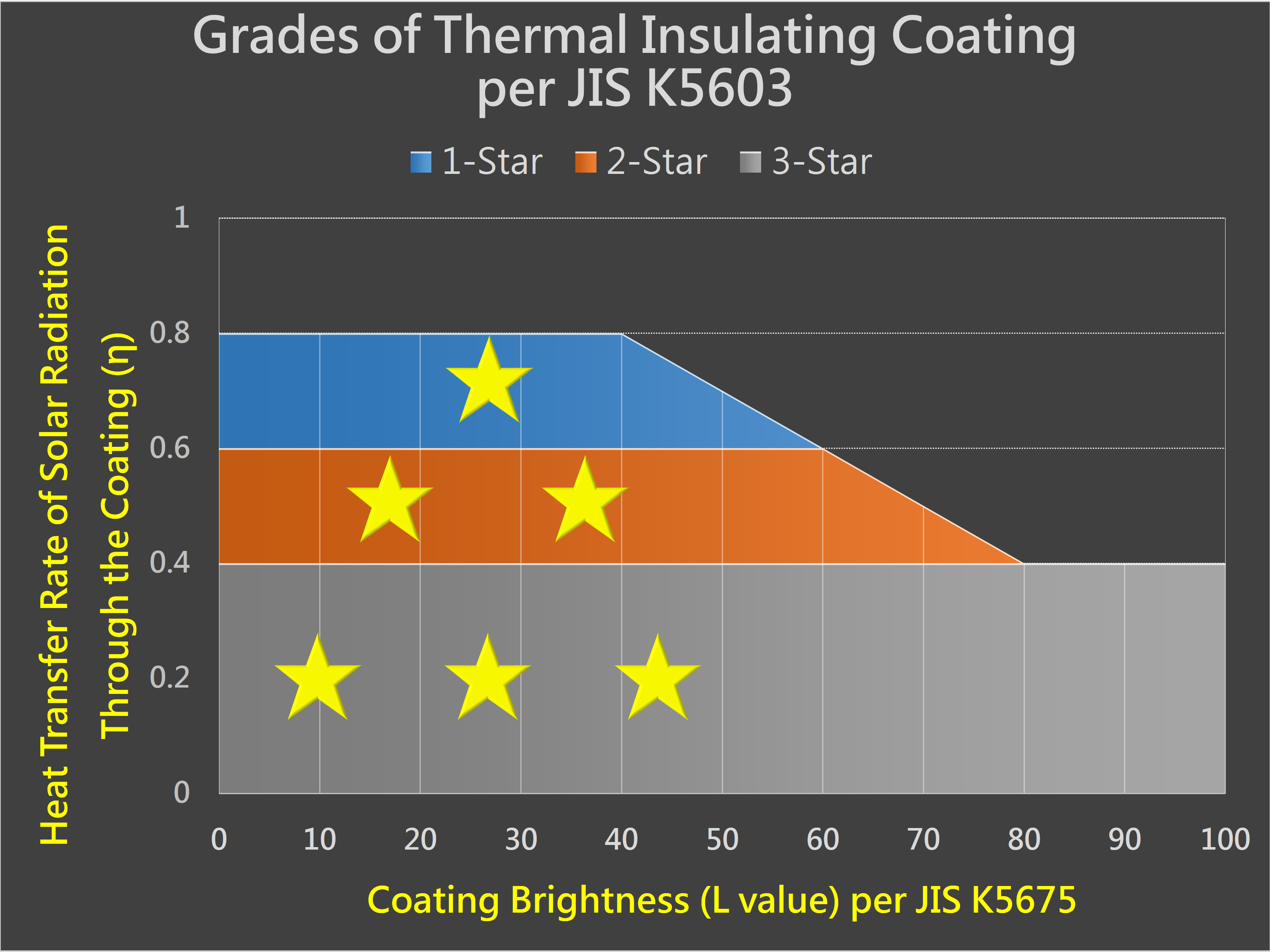

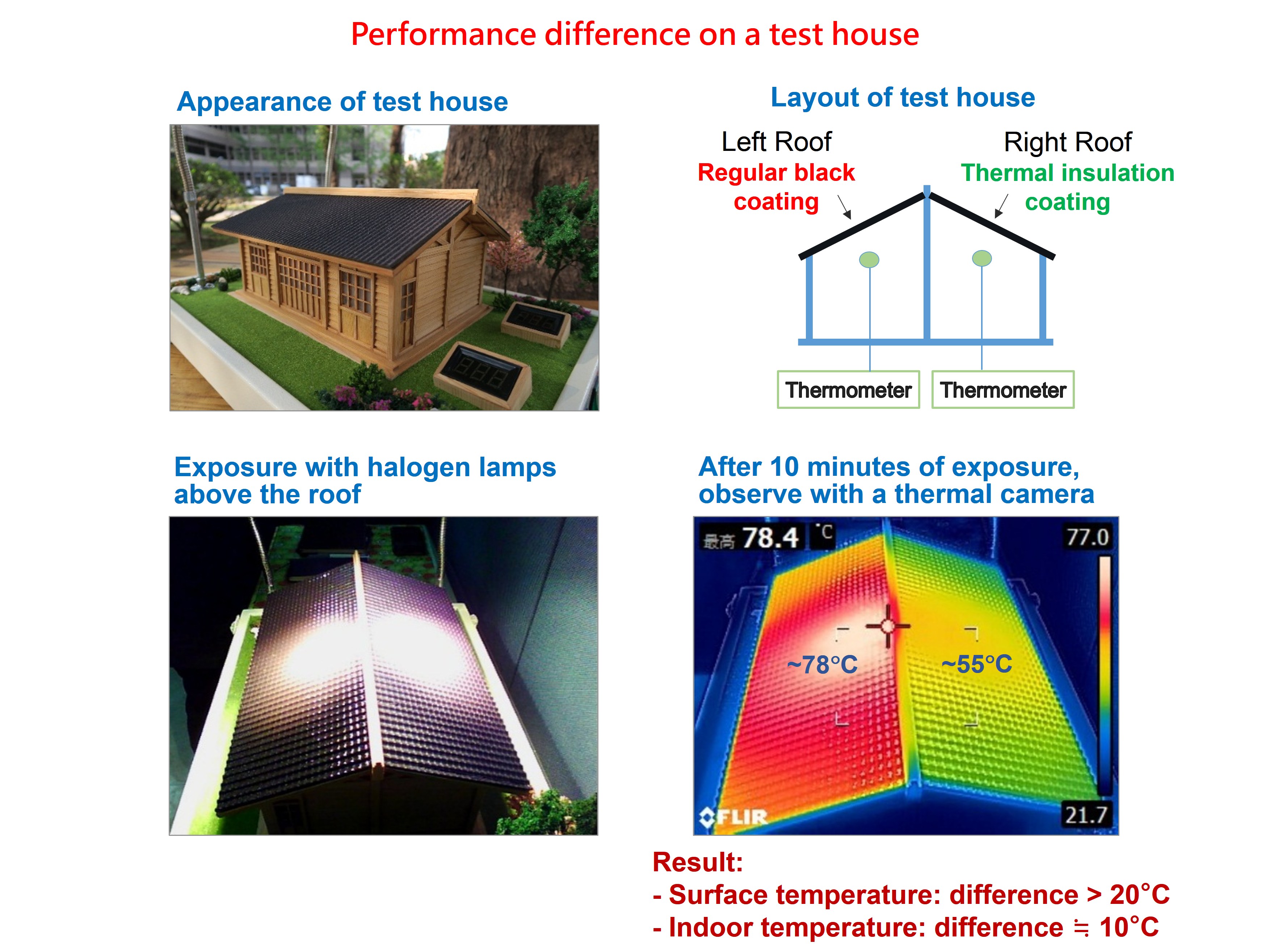

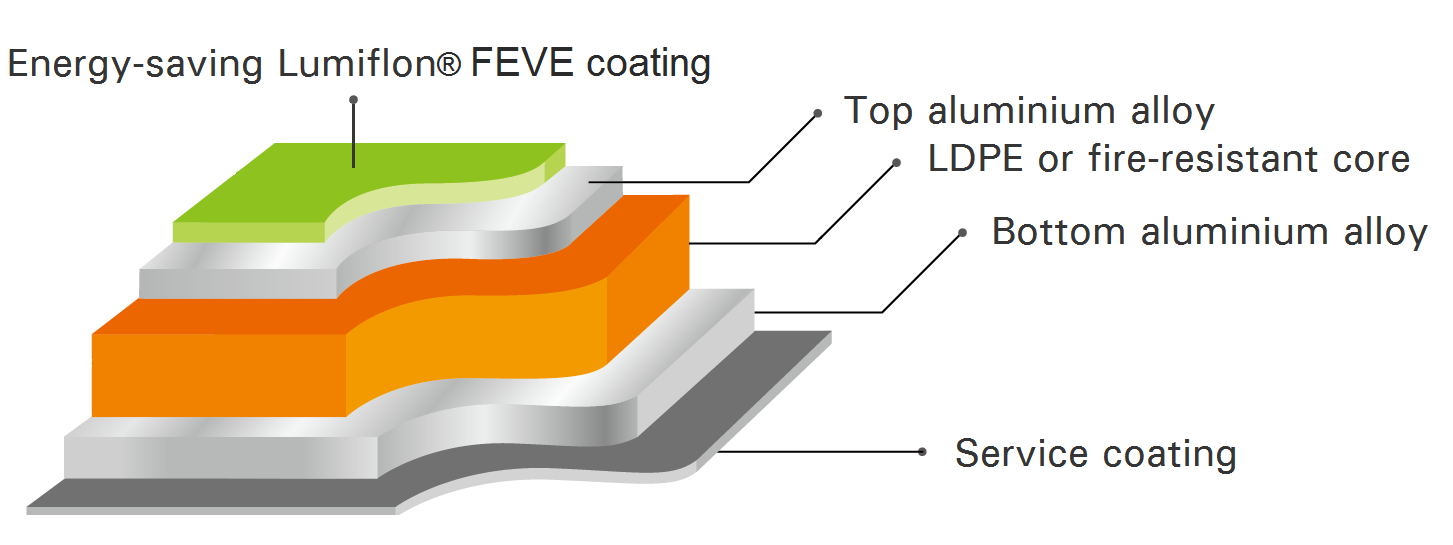

According to statistics, about 41% of solar thermal energy enters the room from the roof and external walls. By using energy-saving building materials the indoor temperature can be effectively reduced, thereby reducing the energy consumption of air conditioning. ALUCOMAT® Energy Smart aluminum composite panel for exterior cladding applications is designed for this purpose. Its energy-saving surface coating adopts the "heat reflective insulation technology" developed in cooperation with one of the national research institute, ITRI, in Taiwan in conjunction with the new generation of Lumiflon® FEVE fluorocarbon resin. It helps to reduce the indoor temperature and further inhibits the urban heat island effect, allowing the exterior walls of buildings to possess the advantages of aesthetic, weather resistance, energy saving and environmental protection at the same time.