【New】ALUCOMAT® EZ Clean

Introduction

In the tropical and subtropical regions, the climate conditions are mostly strong sunshine, high temperature, frequent rainfall, high humidity and serious air pollution with dust particles in the air. The appearances of exterior walls of buildings exposed to such environment get dirty easily and require frequent cleaning and maintenance. However, in case of high-rise buildings, cleaning is difficult, time-consuming and labor-intensive, and incurs extra expenses.

ALUCOMAT® EZ Clean is a new product launched in 2020. Its surface is finished with the functional coating that perfectly combines the "Nano Easy-clean Technology" developed in cooperation with our national research institute, ITRI, and the new generation of fluorocarbon Lumiflon® FEVE paint, which is an ideal solution for exterior wall claddings that get dirty easily due to air pollution problems.

Coating Properties

- Adding nanoscaled easy-clean particles

Nanometer (abbreviation: nm) is a unit of length. One nanometer is equal to one billionth of a meter, which is about one-hundredth of average human hair diameter.

Materials with any external dimension in the nanoscale (1-100nm) are defined as nanomaterials.

Generally speaking, substances at nanoscale exhibit physical, chemical or biological properties that are completely different from those of bulk materials at the macroscopic scale. We use nanomaterial-grade particles to develop the Nano Easy-clean technology to achieve low surface tension and hydrophobicity. The oleophobic and easy-clean effect, combined with the excellent weather resistance of the new generation of fluorocarbon Lumiflon® FEVE coating, not only makes the dust, sludge, oil and gas in the air difficult to adhere to the panel surface, easy to clean and maintain, but also prolongs the lifespan of the exterior wall panels and keeps the building fresh and clean.

|

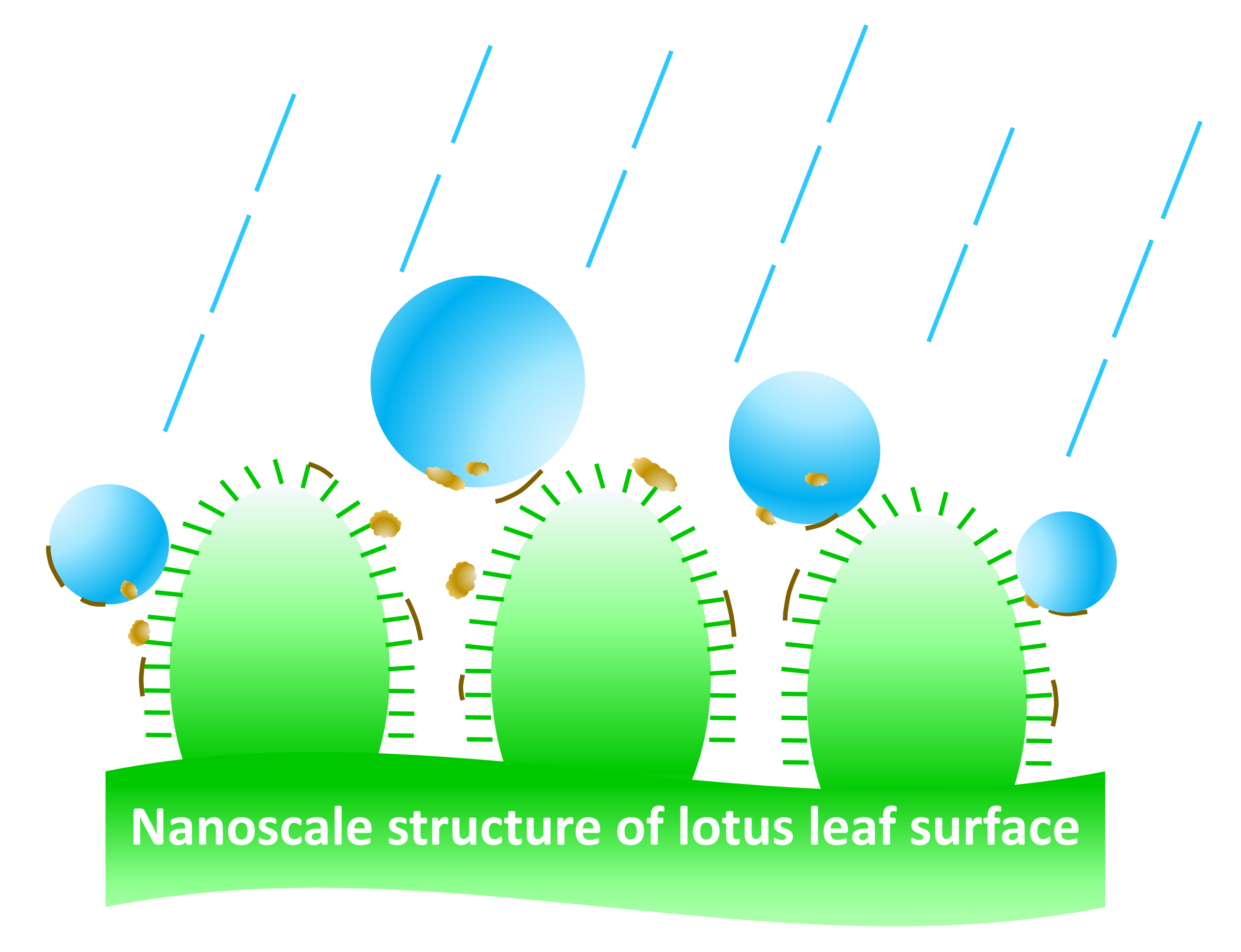

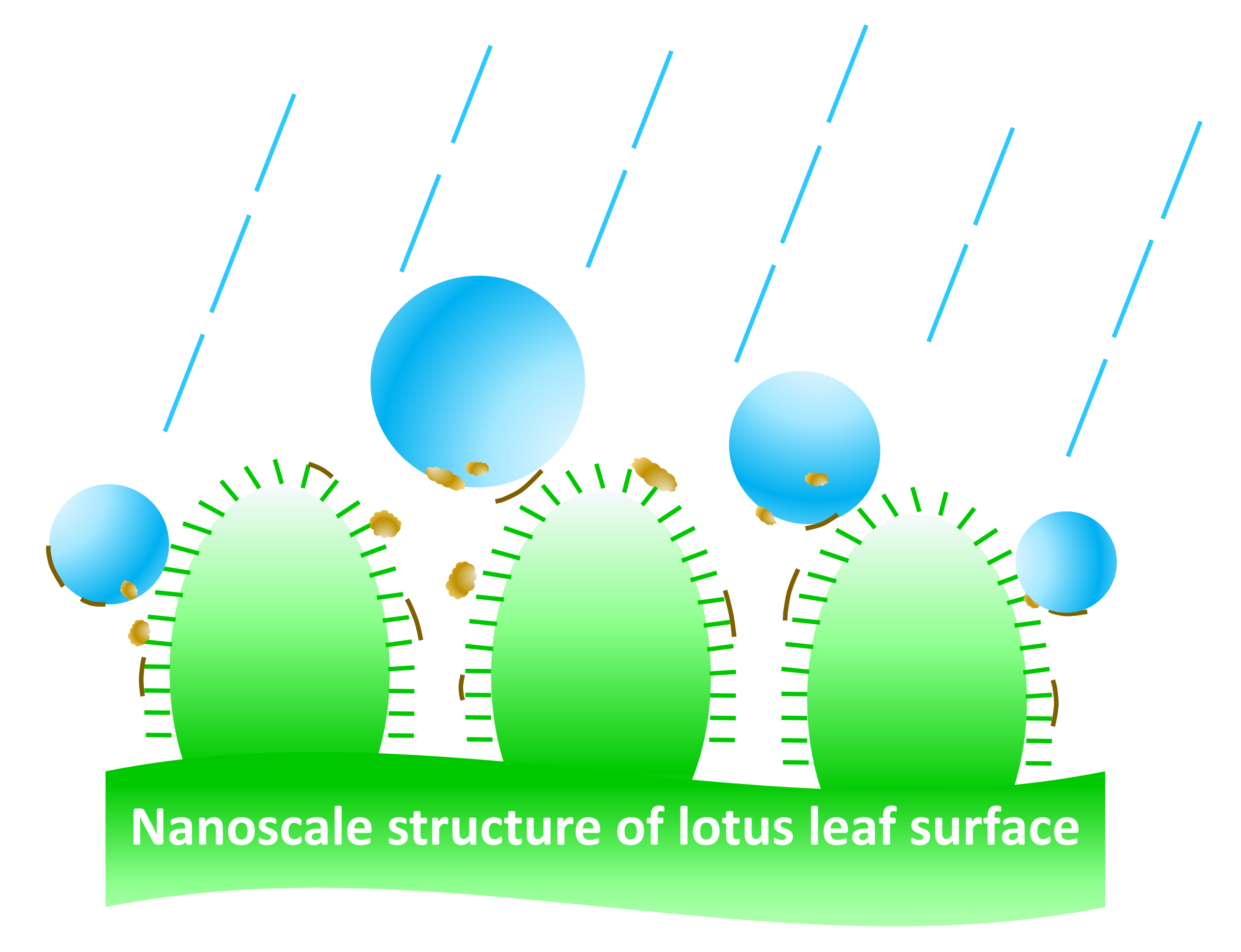

Why does the lotus emerge out of the silt without staining?

The super hydrophobic surface of lotus leaf is the key. It keeps water droplets high contact angle on the surface.

Under the high-resolution electron microscope, scientists find the surface of the lotus leaf has papillary structures with a size of about 5~15 microns, which are covered with nanoscaled cilia-like structures. This nanoscaled surface structure has high hydrophobicity. It’s the reason why the water droplets have high contact angles on the lotus leaf. In fact, not only the water droplets cannot stay, but even the honey is hard to adhere to. Therefore, when the rain falls the water droplets are easy to roll on the lotus leaf, the dusts and sludges gently attached on the surface are taken away together to achieve a clean surface. This is the self-cleaning property of the lotus leaf, also known as "Lotus Effect".

|

The Nano Easy-clean Technology on coating finish we’ve developed in cooperation with a national research institute is simulating above concept to achieve the easy-clean effect of low surface tension, hydrophobicity and oleophobicity. Various pollutants do not adhere easily, and can be washed away by heavy rain or high-pressure water jet. It helps to maintain the cleanliness of the panel surface. |

|

- Amphiphobic effect (hydrophobicity + oleophobicity)

|

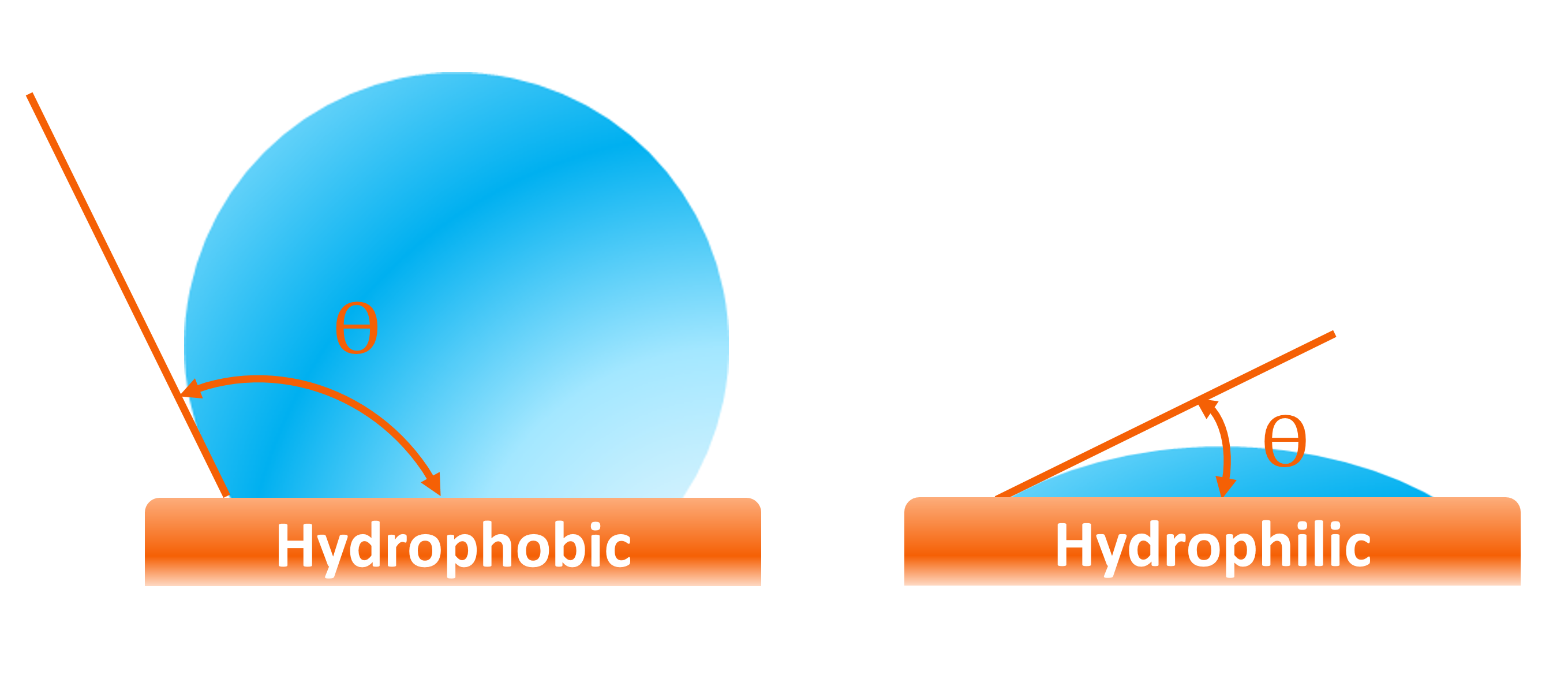

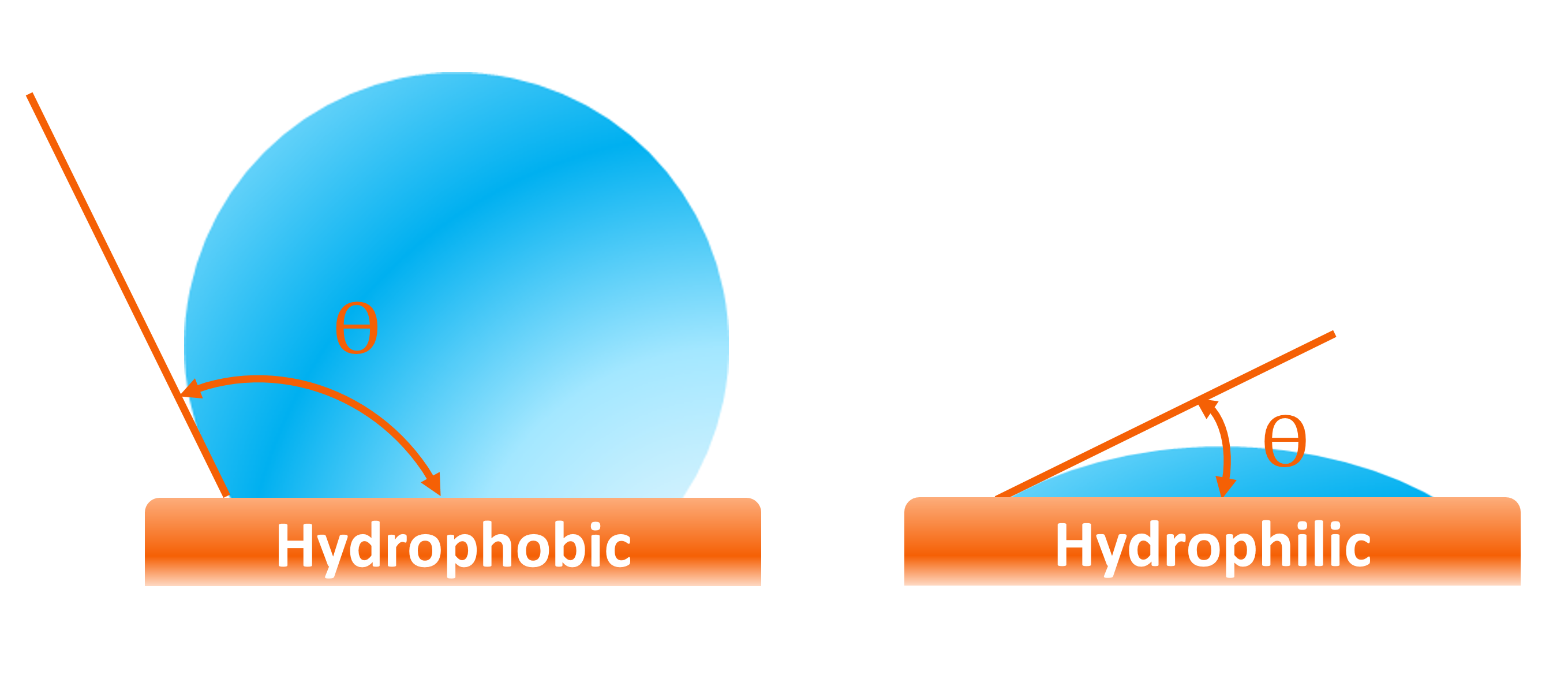

What is Contact Angle (θ) ?

- An important indicator to measure the hydrophilicity and hydrophobicity of the material itself

- Varies depending on surface structures of objects

- The most common measuring method is to drop a droplet on a horizontal soild plane to obtain the θ value.

- Definition of hydrophobicity: water contact angle 80°≦ θ ≦120°

|

|

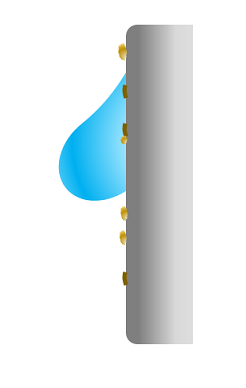

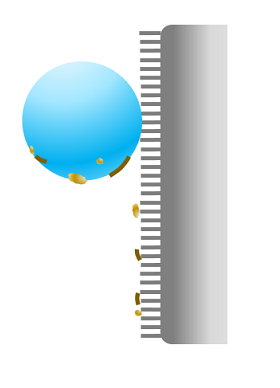

The coating adopted by the ALUCOMAT® EZ Clean series has both hydrophobic and oleophobic effects

| |

Surface of regular coating

|

Surface of easy-clean coating

|

| Oil & ink mixed droplets |

|

|

| Oil & mud mixed droplets |

|

|

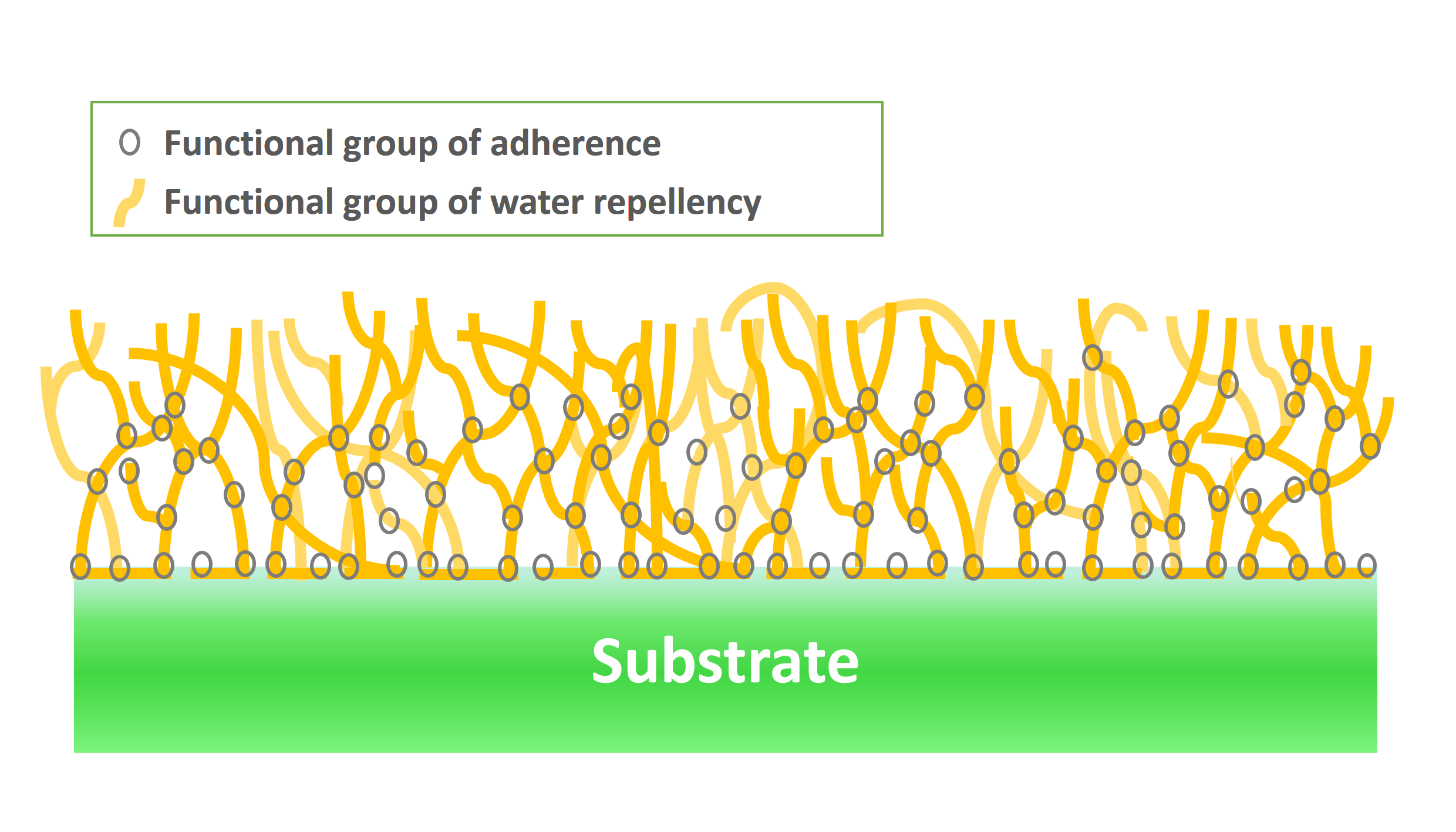

- Long-lasting easy-clean effect

Nanometer (abbreviation: nm) is a unit of length. Different from the short-acting method of additional coating/spraying in the market, we add the nanoscaled particles directly into the coating of ALUCOMAT® EZ Clean series. Their functional groups bond with Lumiflon® FEVE fluorocarbon resin and activate the junction reaction and the unique self-stratification process to create a hydrophobic layer on the coating surface. Thanks to the tight and staggered bonds between the nano-particles and the FEVE resin, the excellent weather resistant property of the resin helps to sustain a durable easy-clean effect, making it less susceptible to UV decomposition. As long as the coating surface is not damaged by external forces the easy-clean effect remains active.

Experiment

Composition

Specifications

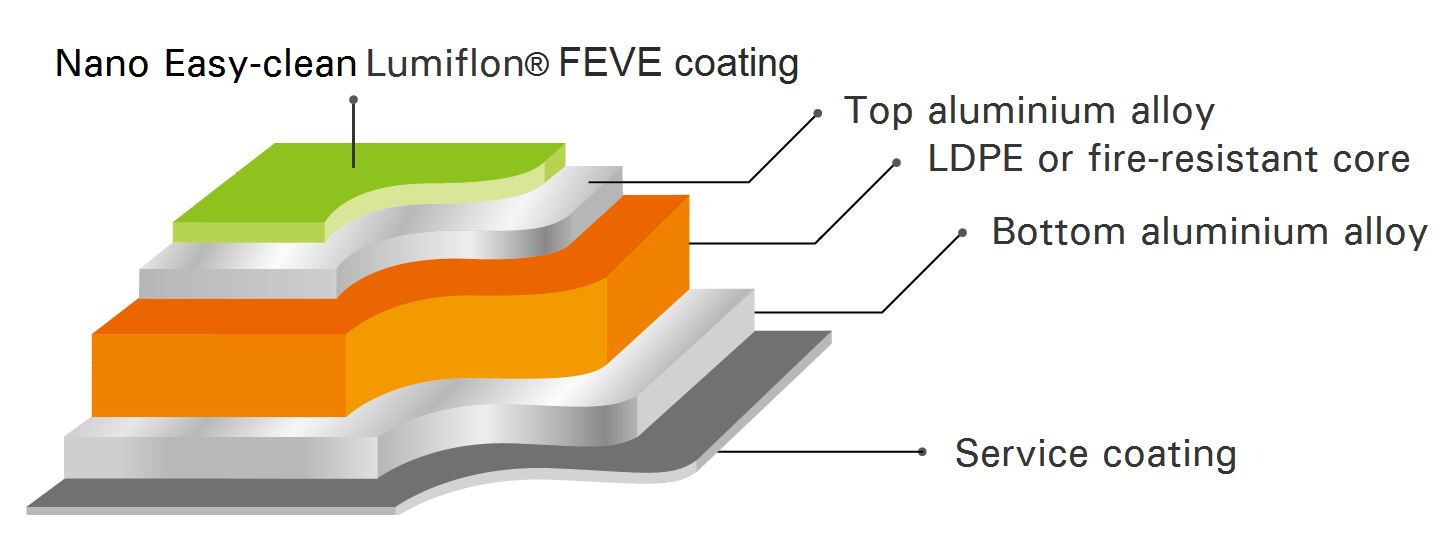

| Since ALUCOMAT® is world’s pioneer of aluminium composite panel since 1966, ALUCOMAT® EZ-Clean specifications are world specifications: |

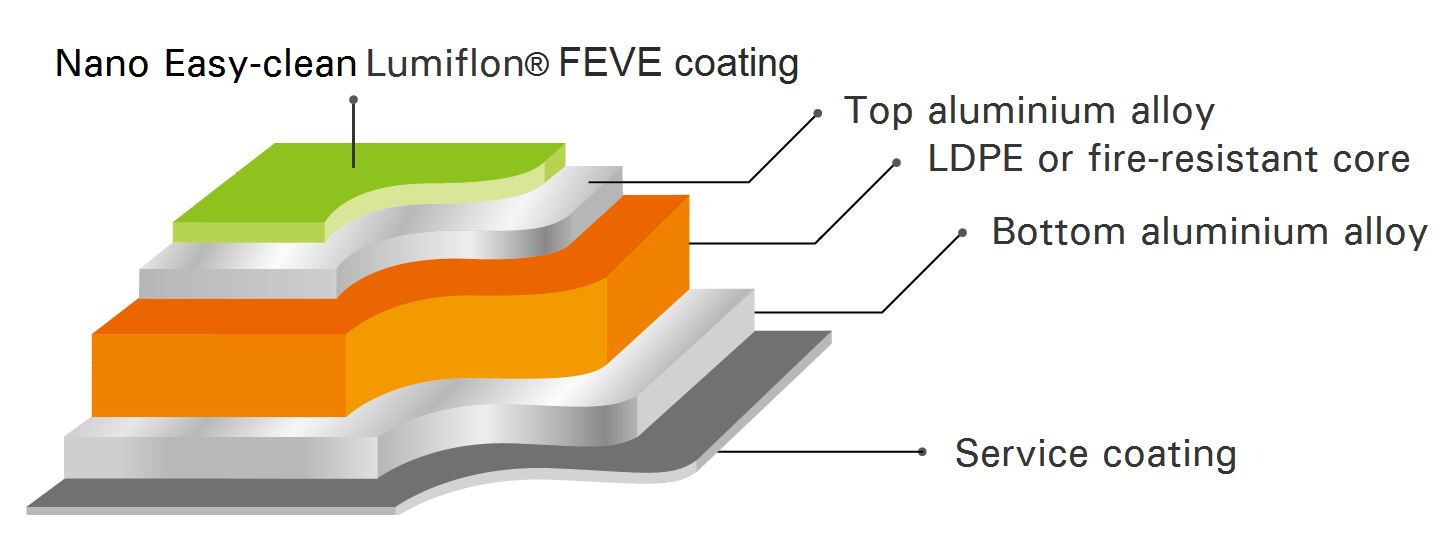

| Alloy |

0.50 mm top-grade, virgin aluminium sheet on each face, refinery certification provided |

| Coating |

Outer face: Nano Easy-clean Lumiflon® FEVE based fluorocarbon coating

Inner face: protected with a service coat (not mill finish) |

| Core |

3mm LDPE, or

3mm fire resistant mineral filled core |

| Thickness |

4.00 mm |

| Width |

1,220 mm |

| Length |

2,440 mm |

| Custom Thickness |

4.0 ~ 8.0 mm |

| Width |

1,250 / 1,500 mm |

| Length |

On demand

|

Total Solution Family

Most of the existing standard colors of ALUCOMAT®, ALUCOMAT® Ti-Zinc, ALUCOMAT® Brushed, ALUCOMAT® Texture, ALUCOMAT® Terracotta, & ALUCOMAT® Chameleon could be upgraded to similar colors of Nano easy-clean formula.

Color Chart

Selected standardized colors are available below for viewing below. Due to color reflection difference on computer monitor, please request actual sample swatch before placing order.