Installation

ALUCOMAT® Aluminium Composite Material (also known as Aluminium Composite Panel) can work with major types of cladding profile systems. Information provided in this section is for preliminary reference. Please refer to ALUCOMAT® Manual and then consult with accredited engineers or technicians as appropriate.

• Fixing ACM (ACP) Cassettes to Cladding Profile Structure

All ALUCOMAT® exterior-class ACM (or ACP) panels are covered with non-transparent protective film before leaving production line.

Removal of protective film is recommended as soon as after installation since under hot and humid weather conditions (such as Southeast Asia, Central America, or the like), residual glue may be left from protective film and stick onto lacquered coated surface of panels.

Once protective film is removed, marker pen, vinyl film or tape are not recommended to be used on lacquered coated surface of panels since particles like acrylic, rubber, epoxy, plasticizers, and solvents employed in these materials will likely to harm coating integrity.

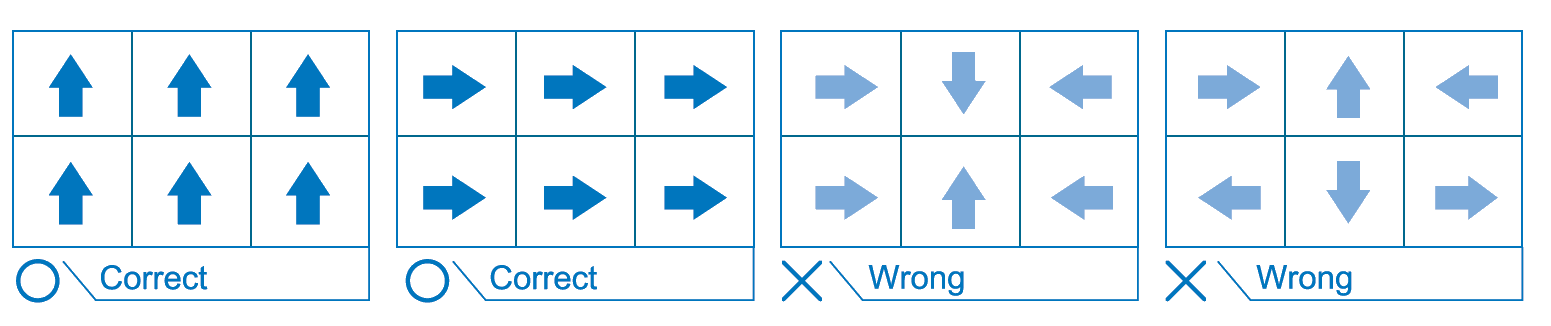

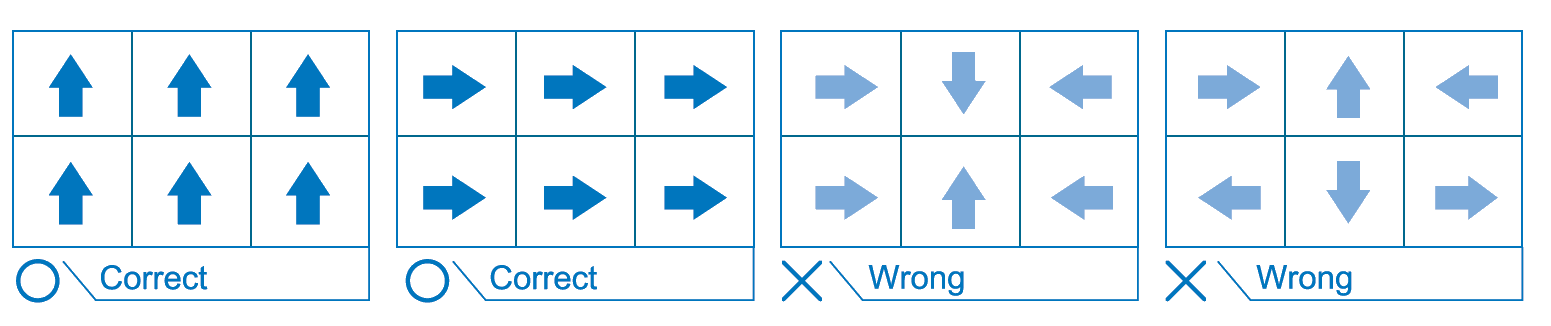

To eliminate the possibility of having color shade reflection difference among panels on single building surface, clients are requested to install all panels only to one single direction according to arrows printed on protective film. See illustration below:

As mentioned in section Storage: Inventory Management, to further eliminate possible color shade reflection difference among panels on single building surface, clients are requested to place all panels required for an identical project within one single order.

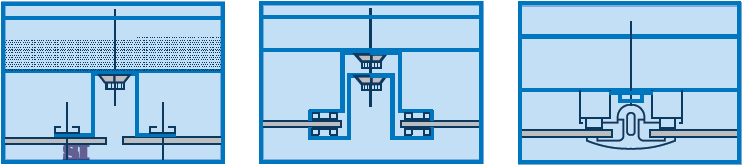

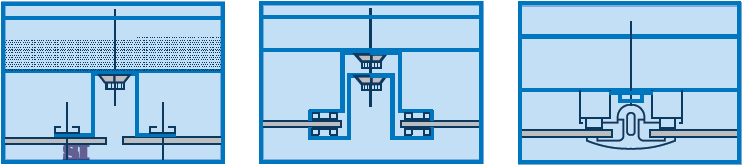

• Single Top Hat • Double Top Hat • Batten & Gasket

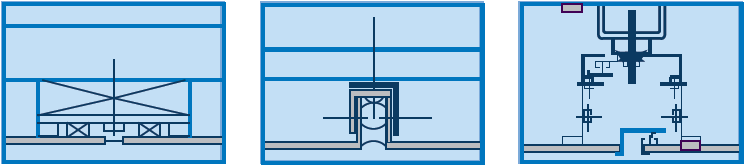

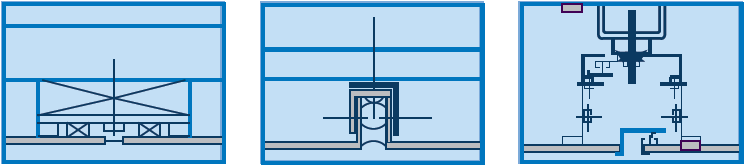

• Silicone Butt Joint • Fixed Cassette • Unitised Curt Wall

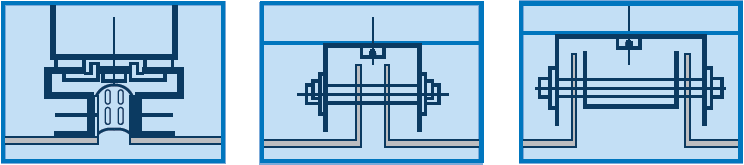

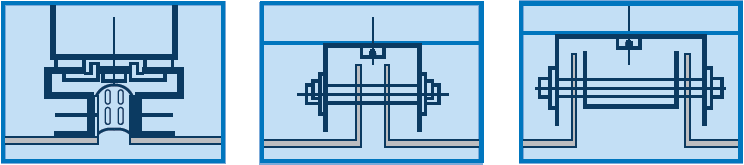

• Clamped Cassette • Suspended Cassette 1 • Suspended Cassette 2

Note that coating integrity will be damaged if working temperature approaches or over 100ºC. Thus thermal resistance of panel itself also has to do with Fabrication.

Demo Clip

• Fixing ACM (ACP) Cassettes to Cladding Profile Structure

Protective Film

All ALUCOMAT® exterior-class ACM (or ACP) panels are covered with non-transparent protective film before leaving production line.

Removal of protective film is recommended as soon as after installation since under hot and humid weather conditions (such as Southeast Asia, Central America, or the like), residual glue may be left from protective film and stick onto lacquered coated surface of panels.

Once protective film is removed, marker pen, vinyl film or tape are not recommended to be used on lacquered coated surface of panels since particles like acrylic, rubber, epoxy, plasticizers, and solvents employed in these materials will likely to harm coating integrity.

Installing Direction

To eliminate the possibility of having color shade reflection difference among panels on single building surface, clients are requested to install all panels only to one single direction according to arrows printed on protective film. See illustration below:

Color Difference

As mentioned in section Storage: Inventory Management, to further eliminate possible color shade reflection difference among panels on single building surface, clients are requested to place all panels required for an identical project within one single order.

Fixing to Cladding Profile Structure

• Single Top Hat • Double Top Hat • Batten & Gasket

• Silicone Butt Joint • Fixed Cassette • Unitised Curt Wall

• Clamped Cassette • Suspended Cassette 1 • Suspended Cassette 2

Thermal Expansion / Contraction

| Change of temperature (either ambient air or heating of construction work) must be taken into account to avoid thermal movement of the panels leading into unacceptable bowing and overstressing of the fasteners. A quick thermal resistance guidance of ALUCOMAT® is as follows: | |

|---|---|

| Thermal Resistance | - 50ºC ~ +80ºC |

| Linear Expansion | 2.40 mm per meter at 100ºC |

Note that coating integrity will be damaged if working temperature approaches or over 100ºC. Thus thermal resistance of panel itself also has to do with Fabrication.